Gauge plate with engraving

Material: Stainless steel

Sheet thickness: 3mm

Surface: Raw

Efficient & precise production

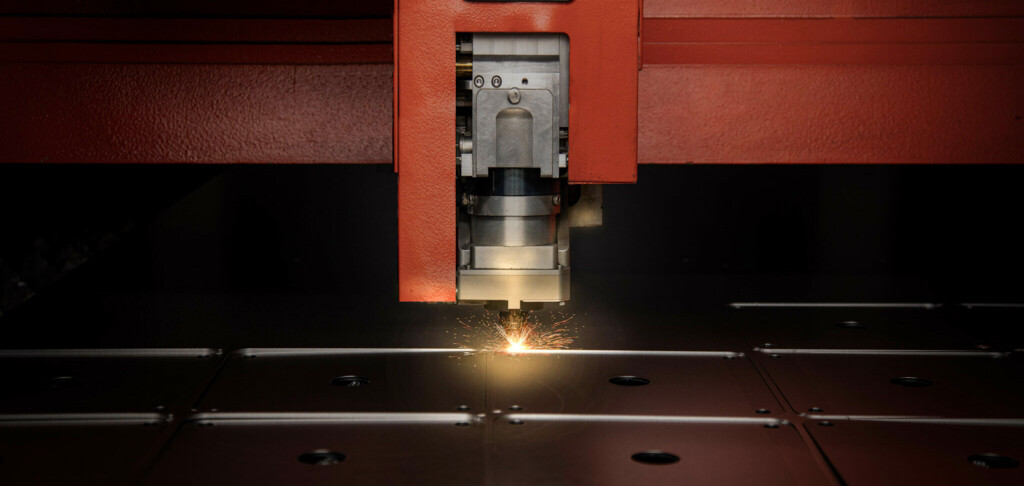

Utilising our advanced laser cutting system, we deliver precise sheet metal components tailored to your specific geometries and material requirements. We efficiently accommodate small batch productions with speed and customisation.

Our production facility is equipped with a 6kw fiber laser system of the latest generation. With this system, we can produce almost all conceivable contours and geometries of laser parts within a very short time. Thanks to the high flexibility of our production, we can also react to your requirements at short notice and produce individual laser cuts.

The appropriate CAD software and our flexible procurement options guarantee our customers a fast and smooth process, from programming to the finished product.

Configure your individual laser cuts online in just a few clicks and get a non-binding quote without registration or technical drawings.

Choose from 5 different materials and shapes as well as various material thicknesses and sheet formats up to 3,000 x 1,500 mm. On request, we can remove all sharp edges, splinters and fraying directly when deburring your laser cuts.

Our fiber laser system scores highly in economical thin sheet metal processing with high efficiency and high part output. The fiber-guided laser is significantly more efficient than a conventional CO2 laser, making production more flexible, faster and more cost-effective. The fiber technology also enables the processing of highly reflective materials such as copper or brass.

We process sheet metal up to a format of 3,000 x 1,500 mm and a maximum sheet thickness of 30 mm - for example, stainless steel.

Your component geometries are created using the appropriate CAD software, in which all the required data and parameters for the material and the respective sheet thickness are taken into account in advance.

You have the option of sending us the desired components in the form of CAD data or transferring the complete design to us. We also develop the right solution together with our customers based on drawings, hand sketches or sample parts. Please use our inquiry form in our laser parts online calculator.

Our programming can be based on your finished data in DXF or STEP format. In principle, other formats can also be used by arrangement.

By combining laser technology and stamping technology, we can react extremely flexibly to a wide range of series sizes and thus offer you as a customer small, medium and large series. The new laser technology also offers the possibility of producing both small parts and large parts with a maximum dimension of 3,000 x 1,500 mm.

For you as our customer, this means flexible procurement and partnership-based support from a single source.

We use our press brake to quickly and reliably form your laser parts into ready-to-install folded parts. The forming options range from simple angular bends to complex edge geometries. A large selection of different bending units enables us to react flexibly and reliably to your requirements.

From small series to large series, we can guarantee efficient, fast and reliable production of your sheet metal parts.