How we work

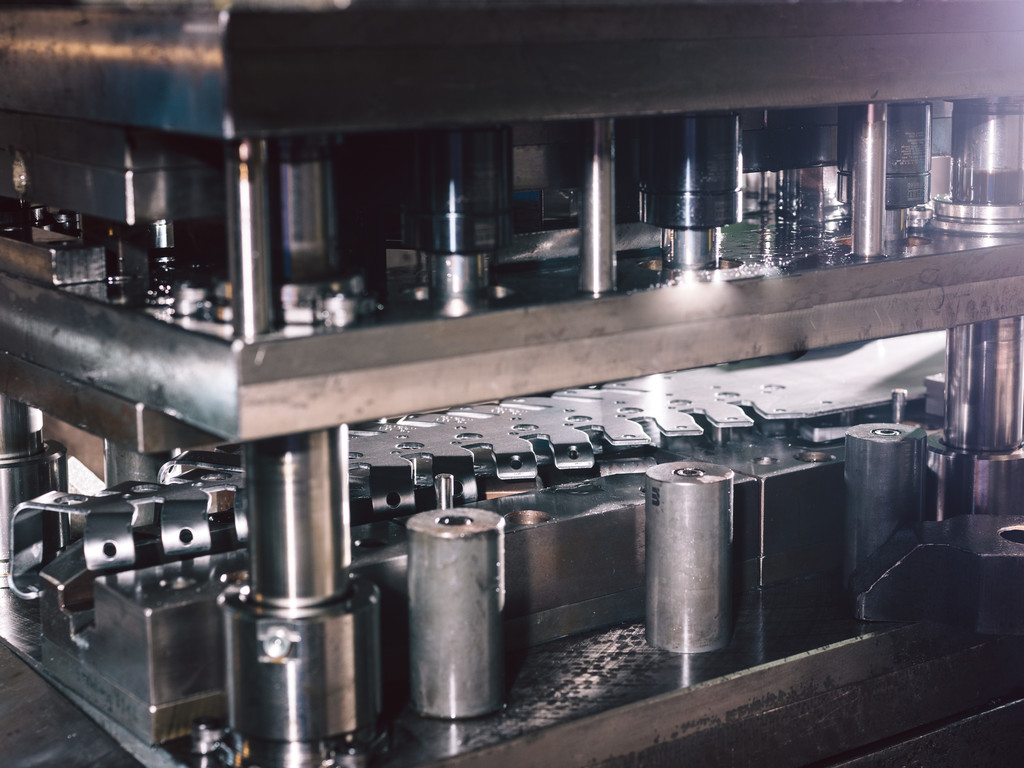

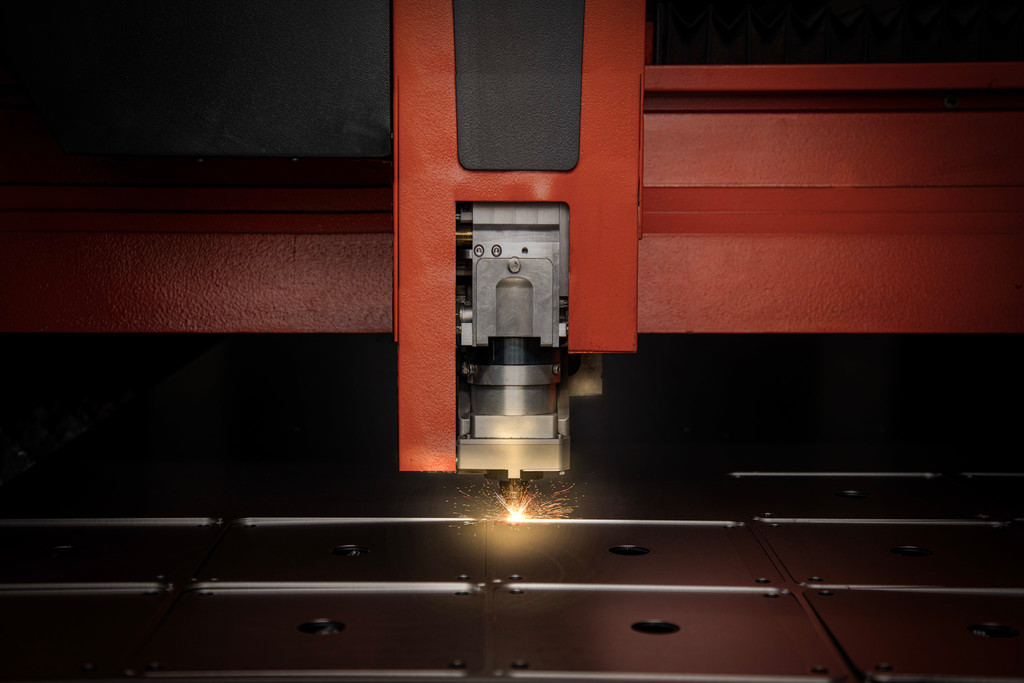

As specialists in the series production of high-quality stamped, bent, and drawn parts, we provide comprehensive solutions for manufacturing a wide range of sheet metal components, from 0.1 to 15 mm in thickness, accommodating both small and large series, as well as assemblies with various surface and edge finishes. The production and assembly of individual components are carried out from a single source. As part of the supply chain process, we also offer you the development and implementation of packaging and logistics concepts to ensure optimum support. The entire process chain, from development to delivery, is accompanied by our integrated and process-securing quality management system.